Automatic L Sealer & Shrink Tunnel

- S5545 is a fully automatic unmanned operation “L” type sealing machine which is widely used in mass production packaging line with high efficiency. Automatic film feeding punching device, manually adjustable film-guide system and feeding conveyor platform make the machine suitable for different width and height items.

- Sealing blade uses the curve 45# carbon steel material integrated knife with USA DuPont Teflon coating which is anti-stick coating & anti-high temperature. So the sealing will not have cracking, coking and smoking with zero pollution;

- Equipped with imported sensor includes horizontal and vertical detection for switching easily, also it’s convenient for packing thin and small items;

- Automatically feeding: the bag length can be auto adjusted by the sensor and time relay. Matched the reduction motor makes the waste film automatically rolling;

| Model | S5545 | T4525 |

| Power | 2kw | 9kw |

| Power Supply | AC 220V 1PH 50Hz | AC 380V 3PH 50Hz |

| Tunnel Chamber Size | / | 1000x450x250mm |

| Max. Packing Size L×W×H | L+1.5H≤530mm; W+1.5H<430mm; L>70mm, H≤135mm; | 1000×300×200mm |

| Efficient Sealing Size L×W×H | L550×W450mm | / |

| Packing Speed | Up to 25 PPM. | 0~20m/min. |

| Seal/Shrink Temperature | 0-300℃ | 0-300℃ |

| External Air Source | 6-8kg/cm2 | / |

| Applicable Shrink Film | POF | POF |

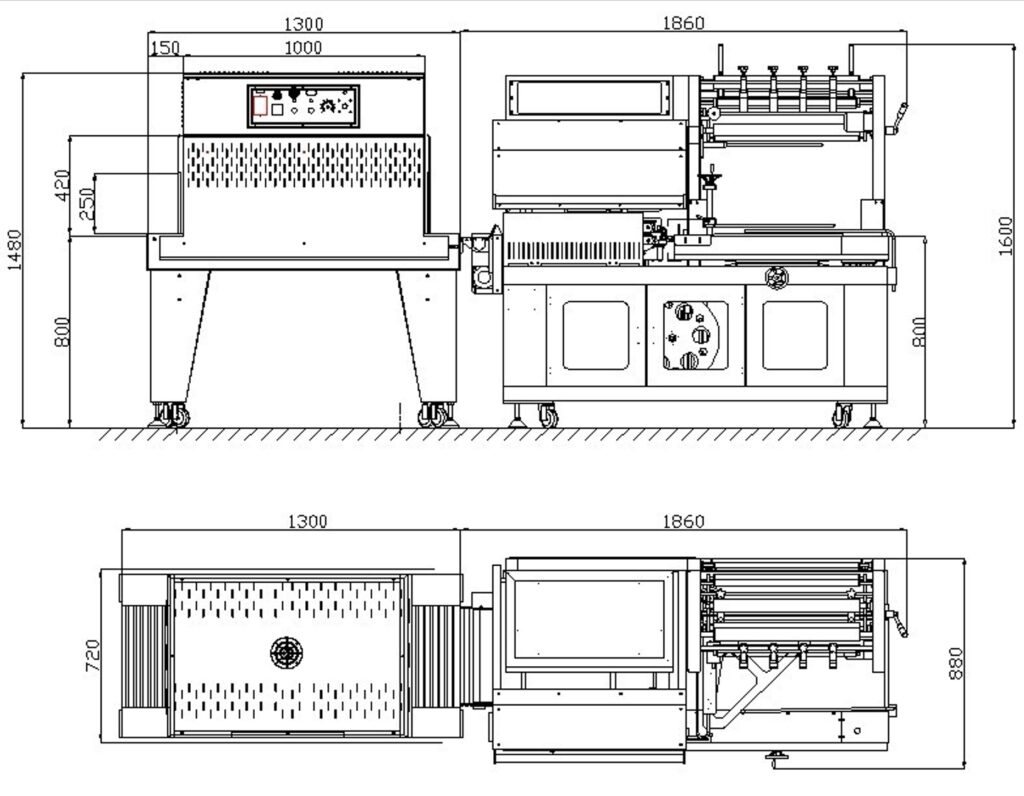

| Machine Size L×W×H | 1860×880×1600mm | 1300×720×1520mm |

| Crate Size L×W×H | 1830×860×1560mm | 1580×770×1105mm |

| G./N. Weight | 480/450kgs | 240/210kgs |

- S5545 is a fully automatic unmanned operation “L” type sealing machine which is widely used in mass production packaging line with high efficiency. Automatic film feeding punching device, manually adjustable film-guide system and feeding conveyor platform make the machine suitable for different width and height items.

- Sealing blade uses the curve 45# carbon steel material integrated knife with USA DuPont Teflon coating which is anti-stick coating & anti-high temperature. So the sealing will not have cracking, coking and smoking with zero pollution;

- Equipped with imported sensor includes horizontal and vertical detection for switching easily, also it’s convenient for packing thin and small items;

- Automatically feeding: the bag length can be auto adjusted by the sensor and time relay. Matched the reduction motor makes the waste film automatically rolling;

- When the packaging size changes, the adjustment is very simple by rotating the hand wheel without changing molds and bag makers;

- Different size products can also be packaged combinations to achieve the promotional effect;

- Using original Autonics digital temperature controller which built-in PID function. Sealing blade temperature is extremely sensitive and accurate and we can be arbitrarily set. Do not worry about hurting the product for imprecise temperature.

- The sealing blade itself is also equipped with automatic protection function which effectively prevent from accidental cutting;

- The machine is equipped with organic glass shield with automatic opening alarm function which greatly improves safety;

- The entire machine realizes unmanned operation with the production line connecting;

- Film up-down synchronization mechanism specially designed to correct the deviation film;

- T4525 adopts imported heating resistant insulation curtain greatly reduces heat loss;

- Stainless steel heating elements makes heating up fast. Circulation fan motor assures large volume air transported evenly.

- Operator can adjust the conveyor speed and tunnel temperature to achieve optimal shrink effect according to products’ sizes and output;

- Using solid roller conveyor, external anti-high temperature silicone tube can load heavier objects and rollers will not be deformed;

- Applies to software, food, cosmetics, printing, pharmaceutical, flooring, ceramic, beverages, hardware and other industries’large quantities of shrink wrap.