Premium Heat Shrink Tunnel

- T6040E using imported double air circulation motors, so that the hot air in the oven can spread more evenly to get a good shrink effect;

- Chain bar conveying, using solid steel covered with durable imported silicone tube.

- T6040E can add density bar roller function which specially designed for small product;

- The use of French “Schneider “inverter controls transmission speed which has the function of infinitive speed;

- The chamber length is short which can greatly reduce the machine power; at same time it maintains good packing effect;

- Film use: PVC, POF, PE;

| Model | T6040E |

| Power | 28kw |

| Power Supply | AC 380V 3PH 50Hz |

| Tunnel Chamber Size L×W×H | 1800×800×400mm |

| Packing Speed | 0-15m/min |

| Shrink Temperature | 0-300℃ |

| Conveyor Height | 825±30mm |

| Shrink Film | PE, POF, PVC,PET |

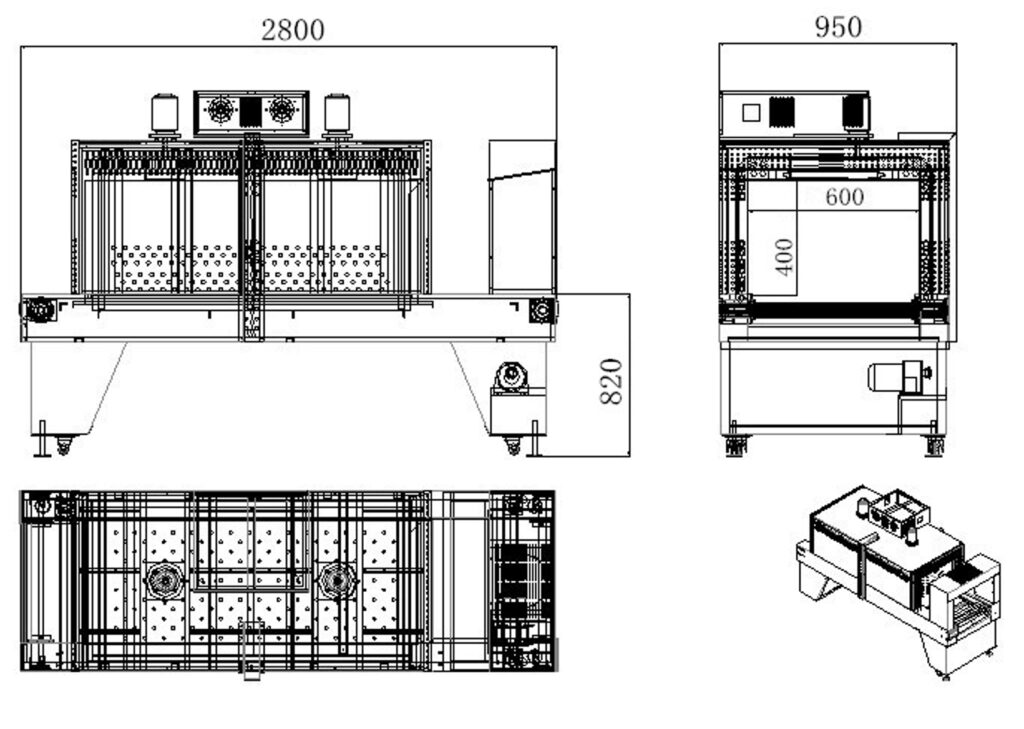

| Machine Size L×W×H | 2800×1050×1750mm |

| Crate Size L×W×H | 2850×1100×1900mm |

| G./N. Weight | 625/565kgs |

- T6040E using imported double air circulation motors, so that the hot air in the oven can spread more evenly to get a good shrink effect;

- Chain bar conveying, using solid steel covered with durable imported silicone tube.

- T6040E can add density bar roller function which specially designed for small product;

- The use of French “Schneider “inverter controls transmission speed which has the function of infinitive speed;

- The chamber length is short which can greatly reduce the machine power; at same time it maintains good packing effect;

- Film use: PVC, POF, PE;

- For beverage, chemical, building material, food packing with or without paper tray. And the tunnel can be used for electrical appliances, auto parts, furniture, flooring and other individual or group sealing and shrink wrap.