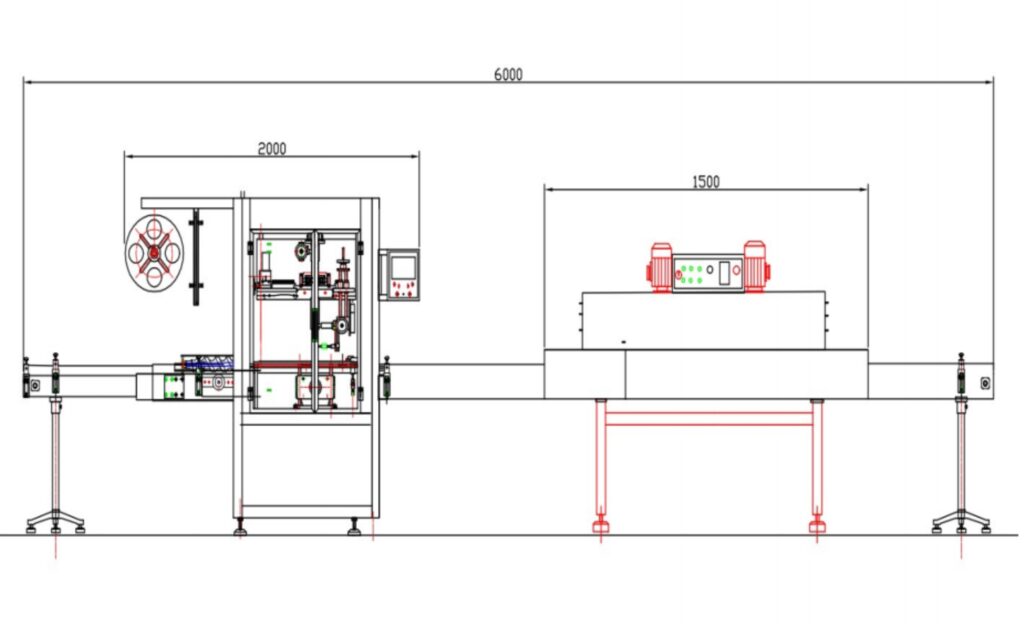

Sleeve Label Applicator & Electrcial Shrink Tunnel

●Synchronous drive, any driving belt replacement may be finished quickly, compared with traditional multiple interlocking belts (its replacement and maintenance need more than 6 hours), the driving belt is easier and simpler to maintain without influences on production.

● Unique cutter head around China, suitable for Φ50mm~Φ135mm containers, the cutter head is completely free of replacement and adjustment, unique touch man-machine interface, namely automatic positioning after searching out origin which is safe and convenient, and is leading the like products.

●Single Contraction Label Feeding Tray: moderate height favors label fixing; automatically controlled by micro-computer; free of setting and adjustment, only need to push the button lightly and then label is in automatic detection & positioning; swift and labor-saving for changing labels, absolutely precise cutting-off position.

●Label feeding part: dynamic-force synchronous tension controls label feeding, feeding capability: 90m/min., Volume label feeding tray: 500mm, applicable internal diameter of paper tube: 4’, 8’, 10’, stable tension of label feeding part ensures the precise of the length of label, stable and fast feeding, and the precise of delivering label and casting label.

Machine | Model of Label Applicator | SL150T |

| Capacity | 50-150BPM | |

| Size L*W*H | 2000*850*2000mm | |

| weight | 600Kgs | |

| Powder supply | 220V 1PH 50Hz | |

| Eligibility percent | ≥99.5% | |

| Total powder | 2.0 KW | |

Shrinkable labels | Materials | PVC、PET、OPS |

| Thickness | 0.03~0.13mm | |

| Labels Length | 40~200mm | |

| Flat width | Max200mm | |

| Inner Dia. Of Labels roll | 3”-10” adjustable | |

Bottles to pack | Height | Max320mm |

| Diameter | Ø50- Ø135mm | |

| Material | Glass, Metal, Plastic | |

| Shapes | Round |

| Model Of Shrink Tunnel | SF-1230 |

| Power | 12kw |

| Power Supply | AC 380/220V 3PH 50/60Hz |

| Max Packing Size Dia×H | 120×300mm |

| Tunnel Chamber Size L×W×H | 2000×180×352mm |

| Packing Speed | 20-40m/min |

| Shrink Temperature | 0-300℃ |

| Shrink Film | PET/PVC |

| Machine Size L×W×H | 2000×850×1516mm |

| Crate Size L×W×H | 2050×900×1666mm |

| G./N. Weight | 350/320kgs |

●Synchronous drive, any driving belt replacement may be finished quickly, compared with traditional multiple interlocking belts (its replacement and maintenance need more than 6 hours), the driving belt is easier and simpler to maintain without influences on production.

● Unique cutter head around China, suitable for Φ50mm~Φ135mm containers, the cutter head is completely free of replacement and adjustment, unique touch man-machine interface, namely automatic positioning after searching out origin which is safe and convenient, and is leading the like products.

●Single Contraction Label Feeding Tray: moderate height favors label fixing; automatically controlled by micro-computer; free of setting and adjustment, only need to push the button lightly and then label is in automatic detection & positioning; swift and labor-saving for changing labels, absolutely precise cutting-off position.

●Label feeding part: dynamic-force synchronous tension controls label feeding, feeding capability: 90m/min., Volume label feeding tray: 500mm, applicable internal diameter of paper tube: 4’, 8’, 10’, stable tension of label feeding part ensures the precise of the length of label, stable and fast feeding, and the precise of delivering label and casting label.

●Stepping casting label part of center guide pillar, casting speed is 50-150B/Min.

●New-type cutter: drive by stepping motors, high speed, stable and precise cutting, smooth cut, good-looking shrinking; matched with label synchronous positioning part, the precise of cut positioning reaches 1mm.

●Multi-point emergency halt button: Emergency halt buttons can be set in proper position of production lines so as to make online execution safe and production smooth.