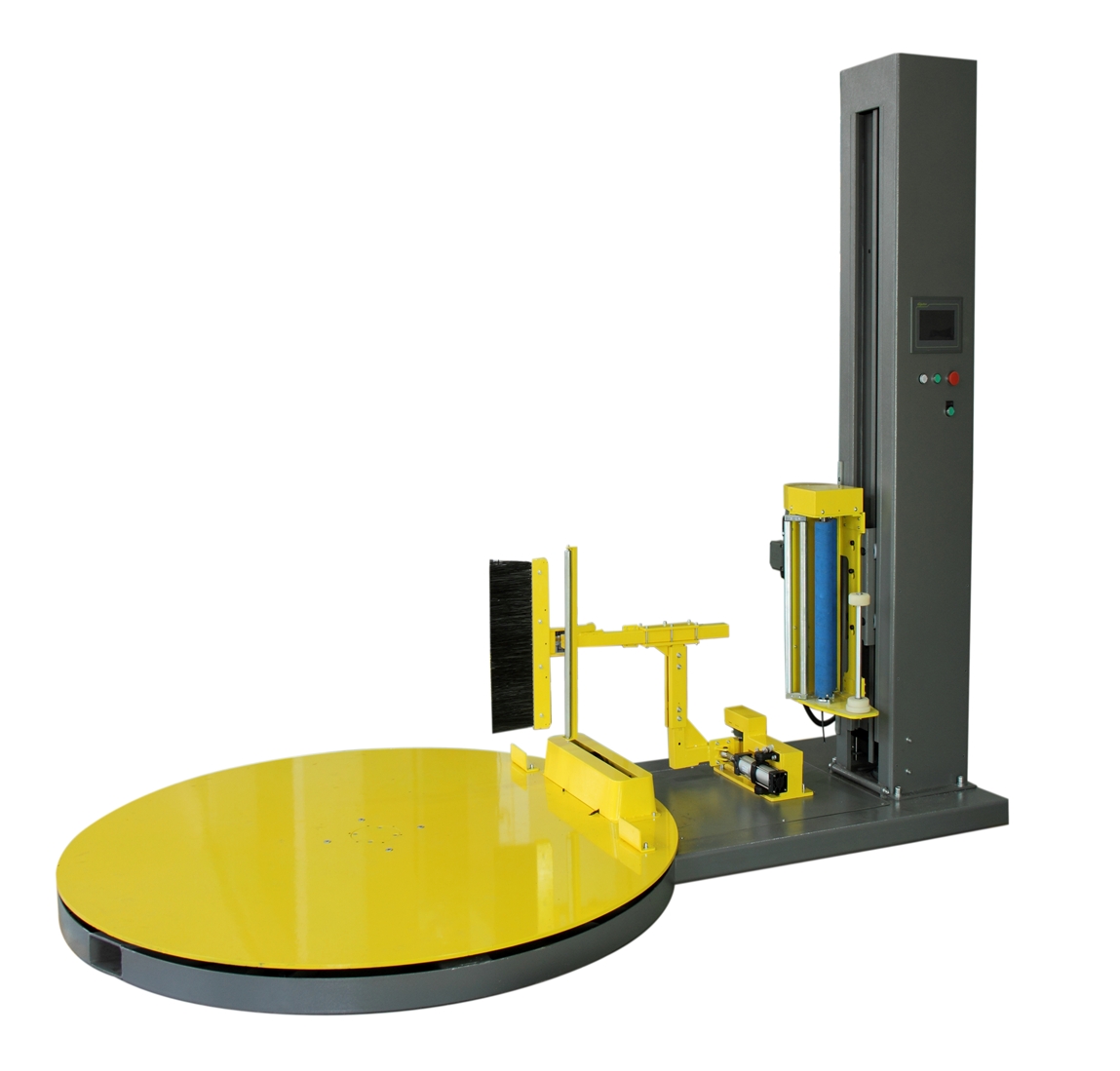

Fully-auto turntable press type pre-stretch wrapping machine SW1650

Working steps:

1.After the turntable slows down, the clamping cylinder acts, the splint stands upright, and the wrapping film wraps the splint and the pallet together

2.The turntable stops rotating, the swing arm cylinder acts, and after the swing arm cylinder is in place, the magnetic switch sends an electrical signal, the clamping cylinder acts, the splint stands upright, and the wrapping film is clamped, and then the film brushing cylinder acts, and the wrapping film is pressed on the goods through the sponge tube on the swing arm, and the heating wire is energized at the same time to cut off the wrapping film.

3.The swing arm turns back to its original position, the magnetic switch of the swing arm cylinder sends an electrical signal, the film brushing cylinder acts, and the swing arm returns to its original position.

4.The new cargo pallet is fed into the turntable, which rotates. After wrapping 2-3 times, clamping plate 1 and clamping plate 2 return to their original positions at the same time. The tightened wrapping film is released. Repeat the above steps after the cargo pallet is packed.

Equipped with automatic film cutting and attaching system

- Turntable diameter: 1650mm

- Turntable table height: 110mm

- Turntable motor power: 0.75kw

- Lifting motor power: 0.37kw

- Pre-tensioning motor power: 0.2KW

- Air pressure: 0.4-0.7MP

- Film cutting method Thermal fuse

- Power supply: 220V, 50HZ, 1PH 1.69KW

- Weight: 700kg

- Packaging efficiency: 10-25 pieces/hour

- Turntable load weight: ≤1500KG

- Photoelectric automatic sensing height and movable limit block limit packaging height can be selected

- The turntable and lifting frequency conversion speed regulation, manual adjustment of the turntable speed, the film carriage rising and falling speed can be adjusted separately

- Manual adjustment of film output tension

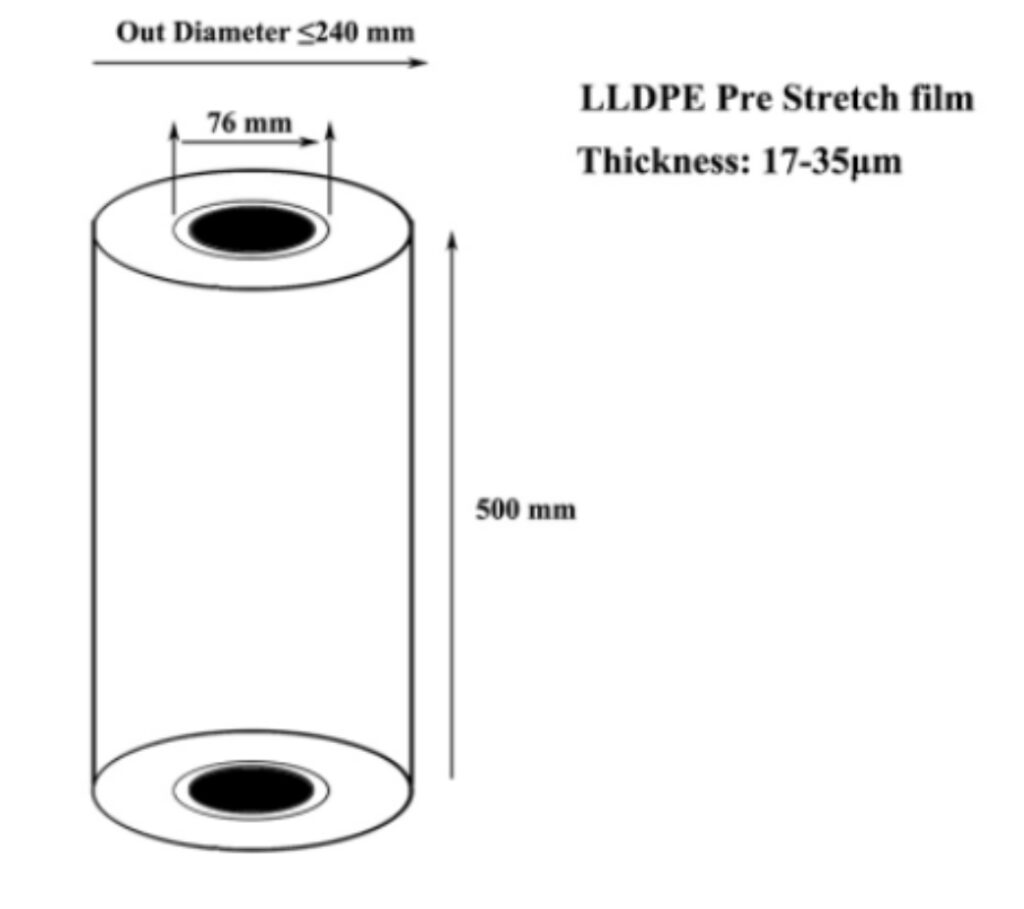

- Pre-stretched film carriage, theoretical stretching ratio 1:2

- Set the top layer number of turns 1-9

- Set the bottom layer number of turns 1-9

- Pneumatic automatic upper and lower film mechanism

Main performance

- Control system

- PLC programmable control, the number of winding layers and times can be changed

Photoelectric switch automatically senses the height of the goods

Automatic control of film upper and lower film stroking process - Turntable drive

Turntable chain drive, slow start, slow stop, automatic reset;

Turntable speed 0~12 rpm frequency conversion speed regulation; - Film system

Open-door film carriage, more convenient for film threading;

Film carriage power frequency conversion pre-stretching mechanism, pre-stretching can reach 200%;

The film carriage lifting mechanism has double chain traction, and the walking device is closed and self-lubricating;

The rising and falling speeds of the film carriage are frequency-controlled, and the film delivery speed is infinitely adjustable;

The top and bottom winding numbers are adjustable separately;

Film follow-up system, active film feeding;