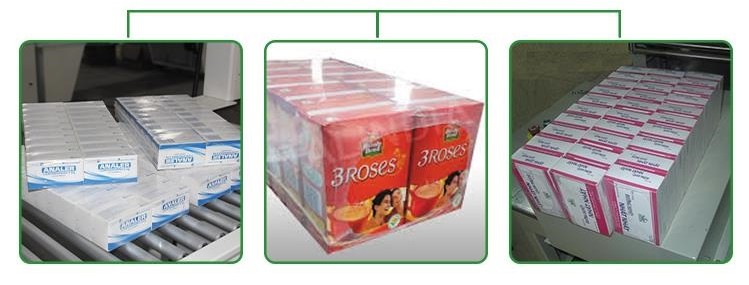

Sleeve Sealer & Shrink Tunnel for Medical Boxes Group Packing

The BSTPACK Pharma series delivers fast, reliable shrink wrapping in a space-saving design, ideal for small pharmaceutical boxes and bottle. These machines produce open-sided (bullseye) secondary packaging and can be customized with a variety of infeed, collation, and bundling configurations. With a compact footprint and high-speed performance, this series is one of the most versatile and efficient packaging solutions available.

Machine Working Video

| Model | S5030AR | T5030E |

| Power | 2kw | 16kw |

| Power Supply | AC220V 1PH 50Hz | AC380V 3PH 50Hz |

| Max Packing Size L×W×H | 300×500×200mm | 1000×400×200mm |

| Tunnel Chamber Size L×W×H | / | 1300×500×300mm |

| Sealing Blade Length | 600mm | / |

| Seal/Shrink Temperature | 0-300℃ | 0-300℃ |

| Conveyor Height | 820±30mm | 820±30mm |

| Packing Speed | 0-12m/min. | Up to 15PPM |

| External Air Source | 6-8kg/cm2 | / |

| Applicable Shrink Film | PE | PE |

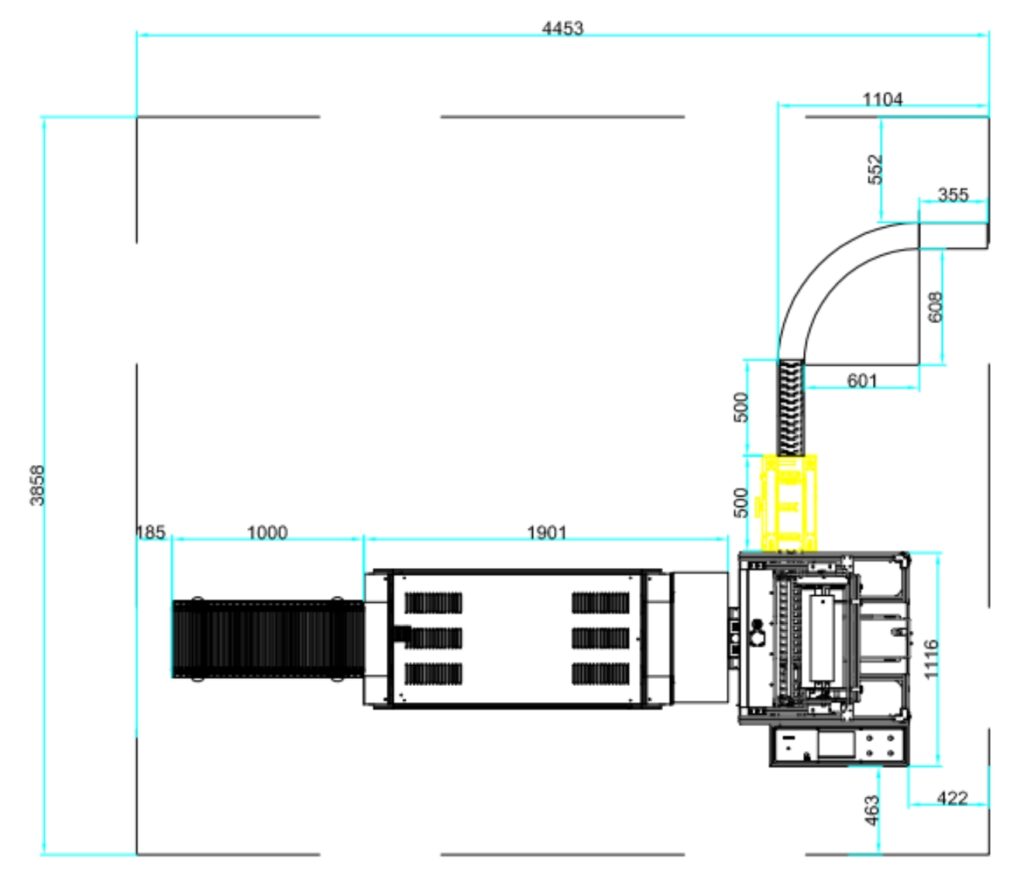

| Machine Size L×W×H | 2220x1000x1467mm | 1900x724x1650mm |

| Crate Size L×W×H | 2270x1050x1617mm | 1950x774x1800mm |

| G./N. Weight | 800kgs/700kgs | 500/400kgs |

- S5030AR + T5030E is suitable for a wide range of shrink wrapping with single or multi-rows products. The automatic alignment greatly improves the production efficiency. After packaging the items have a compact and neat appearance which ensures the items’ quality and integrity of convenience transportation;

- S5030AR adopts international advanced manufacturing technology which is mainly designed for group sleeve packaging of boxes; this machine can automatically form and sort single row or double rows boxes;

- The inlet conveyor belt is able to flip the box from flat to vertical and hold it until the wrapping station;

- The sealing blade is equipped with automatic anti-cutting protection function which effectively prevent from accidental cutting of operator’s hand or products;

- The machine is equipped with organic glass shield with automatic alarm function if the shield is opened, which greatly improves safety;

- The entire machine realizes unmanned operation which can be connect with the existing production line;

- Specially designed up and down film synchronously release mechanism to correct the distance of released film,

- The usage of Siemens PLC and HMl to achieve the integrations of mechanism, electricity and pneumatic;

- Different packing matrix can be selected on the touch screen, while the production capacity can be counted;

- A specially designed sealing blade with Teflon coating makes sure solid sealing line, no cracking and anti-stick;

- Machine can be equipped with color film positioning system (option);

- Using imported Autonics sensors to make accurate positioning of various setting;

- T5030E using imported double air circulation motors, so that the hot air in the oven can spread more evenly to get a good shrink effect;

- Chain bar conveying, using solid steel covered with durable imported silicone tube. T5030E can add density bar roller function or Teflon conveyor belt which is specially designed for small product;

- The use of French “schneider “inverter controls transmission speed which has the function of infinitive speed;

- The chamber length is short which can greatly reduce the machine power; at same time it maintains good shrink appearance;

- Suitable for daily use, cosmetic, stationery and pharmaceutical boxes in multi-row group packaging;